Thermoforming for airplanes

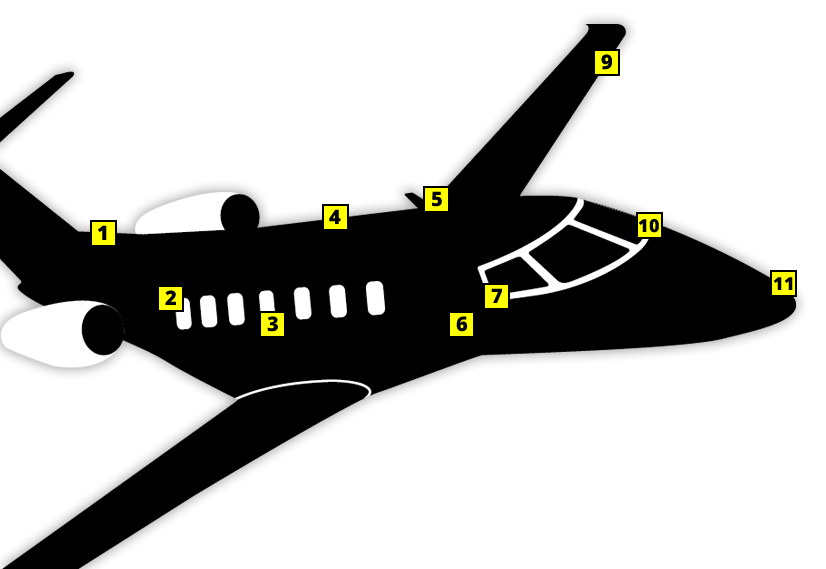

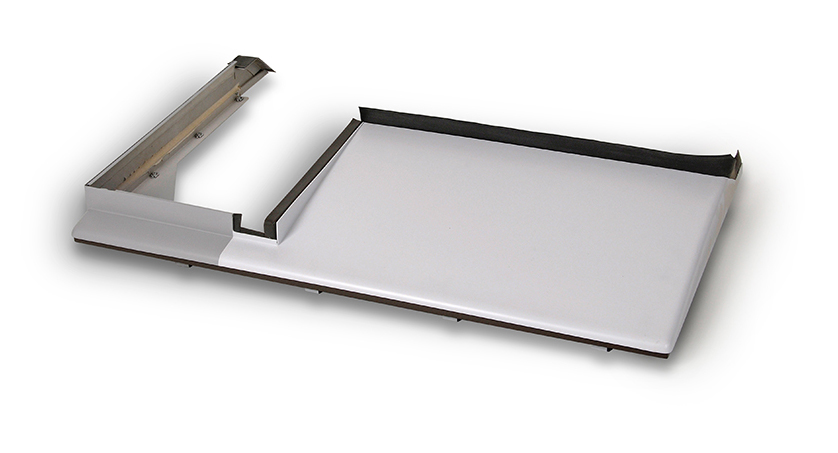

Manufacturing thermoforms for the aircraft industry requires precise processes and high-quality materials. First, heat-resistant plastic panels that meet strict aviation standards are selected. Heating and shaping using precise tools creates precise components such as panels and interior panels. This process enables not only a lightweight but also an aerodynamic design that meets the demanding requirements of aviation. Thermoforming technology is therefore an indispensable step in the production of components for modern aircraft.